A well inspection typically includes assessing the overall condition and operation of the well system.

Includes:

Water Testing:

Owning a private well has numerous advantages, such as having access to mineral-rich water with fewer chemicals, better taste, and lower utility bills. However, maintaining and testing a well requires more effort compared to municipal water. But, there’s no need to worry! In this article, we’ll guide you through the process of inspecting your well, its appearance, and the information you’ll gather from an inspection. With this knowledge, you can confidently enjoy your refreshing well water.

Do you need a well-water inspection?

It’s crucial to test your well water annually as per EPA guidelines because there may be unnoticed environmental changes surrounding your well that could affect the quality and safety of your water. Depending on the homeowner’s specific requirements and concerns, various aspects of a well water inspection can be carried out.

Some common elements of a well water inspection may include:

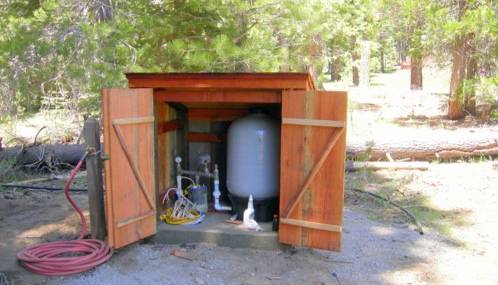

During a well inspection, several areas are typically evaluated to ensure that the well and its components are functioning properly and that the water is safe to use. These areas include:

What is included in a well inspection?

During a well inspection, the primary objective is to assess the functionality of the well and its components while ensuring that the water it produces is safe for human consumption and other uses. The inspectors focus on two major areas, water quality and flow rate, and conduct thorough assessments of specific factors that can impact them.

One crucial factor that inspectors check for is coliform bacteria, which is a broad category of bacteria typically found in the intestinal tract of warm-blooded animals. While most coliform bacteria types are not harmful, some like E.coli can cause serious illnesses, making it essential to evaluate their presence.

Another crucial factor that inspectors assess during well inspections is volatile organic compounds (VOCs). Unlike coliform bacteria, VOCs are harmful and should not be present in the water supply. These compounds come from industrial and petrochemical products that can contaminate water sources for miles, with their presence varying depending on the closest industries. Therefore, regular testing for VOCs is crucial to ensure safe water consumption.

A well inspection may involve an assessment of several elements, including:

Overall, a comprehensive well inspection aims to ensure that the water supply is safe, reliable, and meets regulatory standards for quality and safety.